We are pleased to announce that Szymon Nosewicz from the Department of Information and Computational Science at IPPT PAN has been awarded an OPUS-29 grant by the National Science Centre. The project will be carried out by a consortium.

The project will be implemented by a research consortium composed of experts in materials engineering, solid mechanics, and computational methods in materials mechanics. The consortium consists of the Instytut Podstawowych Problemów Techniki Polskiej Akademii Nauk (IPPT PAN) – the leader, the Łukasiewicz – Instytut Mikroelektroniki i Fotoniki (Łukasiewicz – IMiF), and Vilnius Gediminas Technical University (VilniusTech).

Multiscale analysis of multi-physical properties of novel sustainable energy composite materials: experimental studies and modeling.

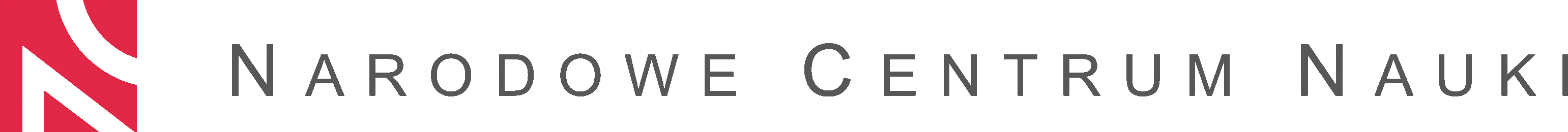

Sustainable energy composite materials represent a cutting-edge solution for modern engineering needs, offering enhanced mechanical properties and durability while promoting energy efficiency and environmental sustainability in construction practices. Incorporating additives like aluminosilicate cenospheres (Figure 1a) into cement matrix composites presents a promising balance between thermal insulation and compressive strength, making them viable alternatives to conventional mortars. These materials deliver practical performance, cost-effectiveness, and efficiency, thus aiding industrial processes to reduce heat loss and enhance energy efficiency.

Despite their attractiveness, sustainable energy composite materials with additives (such as cenospheres) pose challenges due to their complexity and unpredictability. Accurate investigation, particularly in modeling multi-physical properties such as deformation behavior, heat transfer, and acoustic response, is a formidable task due to the intricate material structure (Figure 1b). Utilizing techniques like micro-computed tomography (micro-CT) enables precise reconstruction of the material's inhomogeneous 3D microstructure (Figure 1c), facilitating further simulation of thermal or mechanical properties across different scales. Unlike traditional methods, multiscale analysis considers models at various scales simultaneously, combining the efficiency of macroscopic scales with the precision of microscopic ones.

Fig. 1. Microscopic imaging of ultralight composites with cenospheres done by Authors: a) single cenosphere, b) microstructure with specific features, and c) an example of micro-CT reconstruction of single cenosphere.

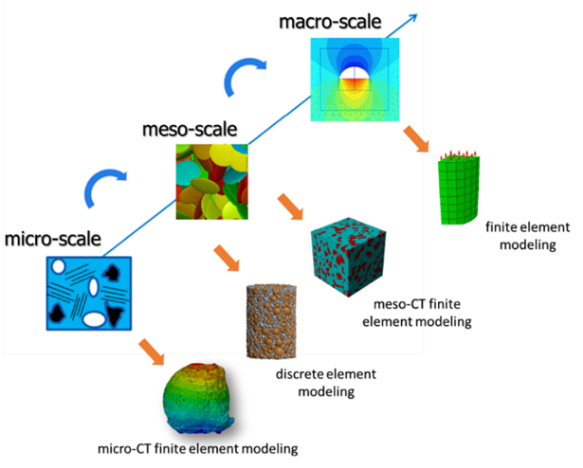

In the proposed project, we aim to develop, implement, and validate numerical and analytical models to predict the multi-physical behavior of innovative sustainable energy composite materials across various scales: microscopic, mesoscopic, and macroscopic (see Figure 2). This involves establishing a multiscale computational framework to assess mechanical, thermal, and acoustic performance, employing diverse approaches and numerical models tailored to each scale. The top of the multiscale approach will be regarded as a numerical framework allowing the optimization of the manufacturing process of ultralight composites and their mechanical, thermal, and acoustic characterization.

The numerical model will be validated using data from our own multiscale experimental research, focusing on mechanical, thermal, and acoustic domains. We will test specific composite compositions featuring varying proportions of calcium aluminate cement (as the matrix) and different types of reinforcement. Three types of reinforcement have been selected for evaluation: aluminosilicate cenospheres, expanded glass granules derived from recycled glass with varying fractions, and granules produced from dusty materials during the granulation process.

Fig. 2. Overview of new multiscale numerical model at different length scales