IPPT PAN has commenced research work under the project "Manufacture of measuring probes with various tip shapes and unique mechanical and tribological properties for use in atomic force microscopes.". This work is financed by the National Center for Research and Development (NCBiR) and the National Science Center (NCN) as part of the TANGO IV joint venture. This is the fourth edition of the program aimed at supporting the commercialization of the results of basic research.

The contractor for the project is a consortium consisting of IPPT PAN and PIK Instruments. The project aims to introduce to the market innovative measuring probes for atomic force microscopes (AFMs) by PIK Instruments. Thanks to the new technology for the production of probes for AFM proposed at the Institute of Fundamental Technological Research (IPPT PAN), it will be possible to produce probes made of any material that can be deposited in the form of a thin layer using galvanic or PVD deposition methods and with any convex shape of the measuring tip. Such probes will be cheaper and more durable than their silicon counterparts and will allow for equally precise performance of standard measurements such as surface topography measurement, lateral force measurement or measurement using the Kelvin probe method. Additionally, our probes will have properties and parameters, which will allow you to perform a number of measurements that until now have been difficult or even impossible, e.g. measurements of friction coefficients in specific friction pairs, wear measurements, nanoindentation or biological measurements.

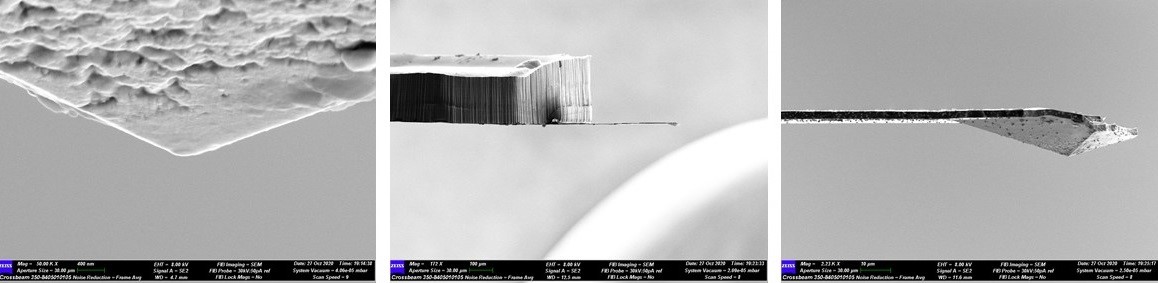

Briefly, the test probes will be produced by making an impression with an indenter of a suitable shape in a plastic substrate, fabricating the mask, applying the probe material and etching the substrate. It should be noted that so far the technology from IPPT PAN has made it possible to produce nickel probes on a copper substrate. In the project, we would like to expand the production possibilities with conductive probes made of gold, silver, cobalt or chromium, and probes made of superhard materials such as boron carbides or DLC. One of the indirect goals of the project will also be to adjust the parameters of the probes to the strict requirements of customers - not only in terms of resolution or measurement accuracy, but also in terms of aesthetics and ease of installation.

The project manager is dr hab. inż. Dariusz Jarząbek