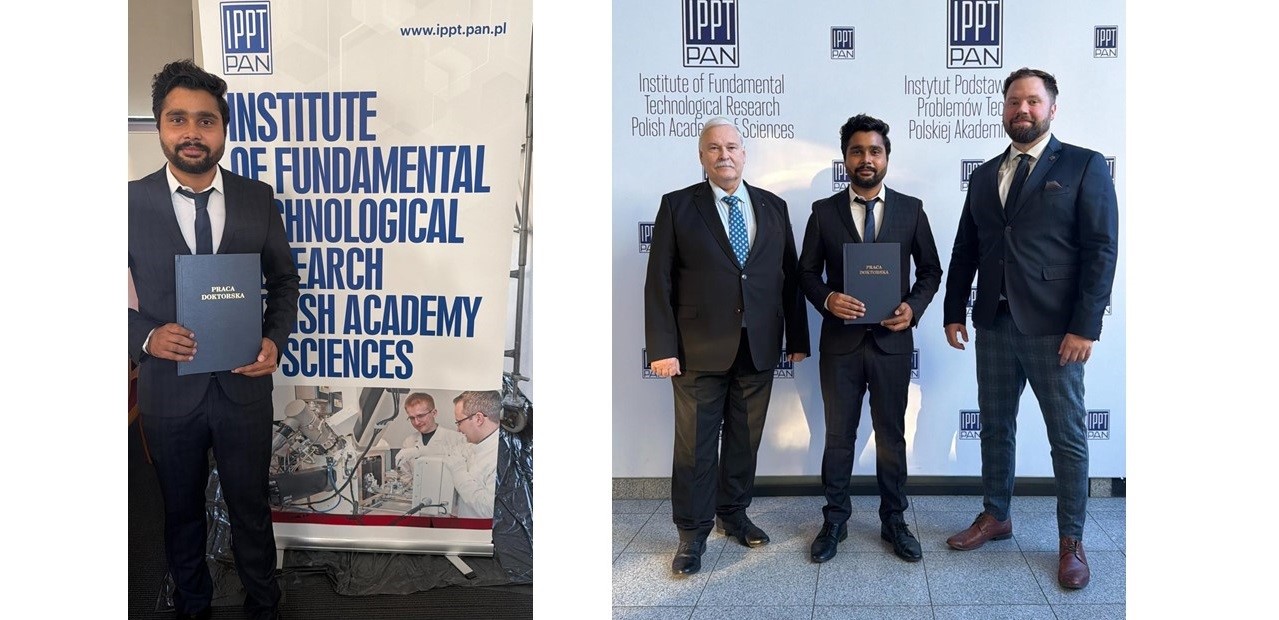

We are pleased to announce that the Scientific Council of the IPPT PAN has awarded Ved Prakash Dubey the degree of Doctor in Engineering and Technical Sciences in the discipline of Mechanical Engineering. The title of his dissertation is “Yield Surface Identification of Functional Materials and Its Evolution Reflecting Deformation History under Complex Loadings.” The dissertation was supervised by Prof. Zbigniew L. Kowalewski, with Assoc. Prof. Mateusz Kopeć of IPPT PAN serving as assistant supervisor. The dissertation was awarded with distinction.

The present doctoral Thesis investigates the yield surface identification and its evolution in functional metallic materials under complex loading paths, reflecting pre-deformation histories. The experimental study focuses on CP-Ti (Commercially Pure Titanium), CP-Cu (Commercially Pure Copper), Ti-Cu bimetal, and SS316L stainless steel, offering significant insights into their anisotropic mechanical behaviour and strain-hardening mechanisms. The research addresses the lack of comprehensive data on the impact of pre-deformation on yield surface evolution, a crucial aspect in design engineering and manufacturing processes.

The experimental methodology employs the single specimen approach combined with the sequential probing technique, where the yield surface was identified at various plastic offset strains. The Szczepiński yield criterion was utilized for yield surface approximation. The initial yield surface and its subsequent evolution were determined after pre-deformation induced by uniaxial tension and combined tension-cyclic torsion loading. The results reveal that pre-deformation substantially influences the size, shape, and position of the yield surface, with distinct effects depending on the loading path and material type.

The findings of combined tension-cyclic torsion loading on the mechanical properties of CP-Ti, CP-Cu, and Ti-Cu bimetal indicate a significant reduction in axial stress, with the magnitude of softening increasing with torsional strain amplitude and frequency. Moreover, the anisotropic nature of the initial yield surface of CP-Ti, likely resulting from manufacturing processes, was confirmed through EBSD texture analysis. Whereas, the size of subsequent yield surfaces after pre-deformation of the CP-Ti were reduced in all directions, except of that representing the pure tension. In the case of CP-Cu, pre-deformation through monotonic tension resulted in kinematic hardening, shifting the yield surface in the pre-strain direction. Conversely, combined tension-cyclic torsion pre-deformation induced anisotropic hardening at lower torsional amplitudes and anisotropic softening at higher amplitudes. The dominant influence of torsional strain amplitude over frequency highlights the complex interplay between loading direction and strain path. For the Ti-Cu bimetal, the yield surface evolution reflects the combined mechanical properties of its constituents. The observed kinematic hardening following monotonic tension and kinematic softening after combined loading indicate the critical role of microstructural changes in the bimetal's mechanical response. EBSD analysis confirmed that shear strain magnitude during combined loading triggers recrystallization and the activation of additional slip systems, leading to yield surface anisotropy. The investigation of SS316L explored the yield surface evolution in both wrought and LPBF-printed (Laser Powder Bed Fusion) specimens across different printing orientations. The layer-by-layer additive manufacturing process introduced directional dependencies in yield strength, with Z-oriented specimens exhibiting the lowest mechanical performance. Pre-deformation through monotonic tension resulted in varying degrees of softening, influenced by both material morphology and pre-strain level.

The findings of this Thesis contribute to the broader understanding of anisotropic plasticity and yield surface evolution in metallic materials, offering valuable data for the development of advanced constitutive models in computational mechanics. The experimental validation of the Szczepiński yield criterion highlights its potential as a powerful tool for predicting the mechanical response of materials under complex multiaxial stress states. The outcomes of this study hold significant implications for the design, manufacturing, and structural optimization of functional materials in aerospace, automotive, and biomedical applications.