Dr Anna Liguori from the University of Bologna will carry out a project at IPPT PAN together with Filippo Pierini, PhD, DSc from the Department of Biosystems and Soft Matter. The project will be financed by the EEA Grants and Norway Grants as part of the POLS competition.

Norway Grants and EEA Grants, i.e. the Norwegian Financial Mechanism and the European Economic Area Financial Mechanism are a form of non-repayable foreign help contributed by Norway, Iceland and Liechtenstein for the new EU members.

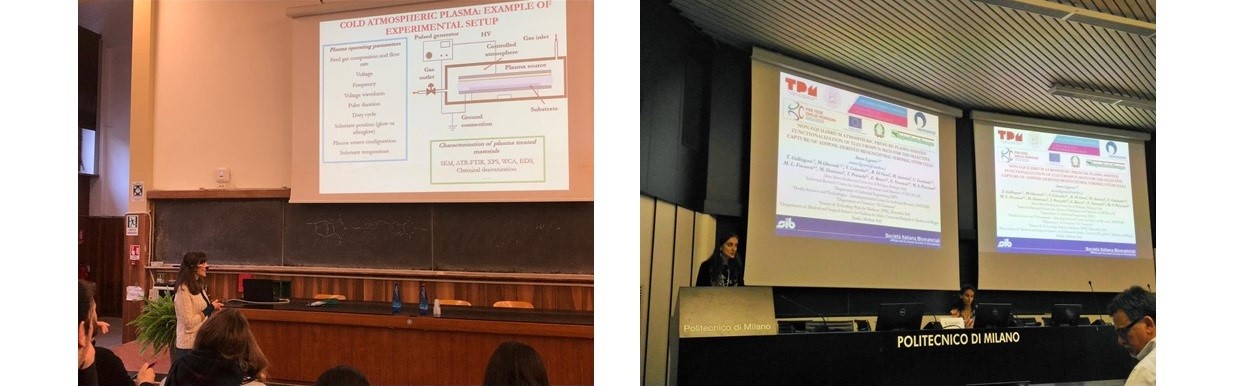

Anna Liguori has been working at the University of Bologna since 2016. From January 2013 to December 2015, she undertook her Ph.D program in Mechanical and Advanced Sciences of Engineering, defending the theses "Functional modification of materials and synthesis of nanostructures by non-equilibrium atmospheric pressure plasma processes". Her research activities mainly concern the design and optimization of cold atmospheric plasma assisted processes for the surface modification of materials, crosslinking of polymers, deposition of polymeric and nanocomposite coatings, synthesis of nanostructures in liquid environment, for industrial and biomedical applications. She has authored 24 scientific publications on international journals.

Project: Personalized scaffolds for regenerative medicine: integration of shape-memory polymers, additive manufacturing and electrospinning technologies, SMART

In the fields of regenerative medicine and tissue restoration, scaffolds need to show geometries close to the patient’s anatomy in order to avoid undesired effects, spanning from the implant migration to its inefficacy due to the lack of anatomic conformity, which can lead to severe medical complications, such as insurgency of inflammations, infections and necrosis. In this frame, the production of personalized devices, such as 3D-printed implants and electrospun scaffolds, is an interesting solution to obtain materials with geometries fitting the patient’s anatomy, thus significantly decreasing the risk of complications. However, the procedure for the achievement of personalized implants or scaffolds could be time-consuming and, in some cases, incompatible with the urgency imposed by the patient’s conditions.

In order to overcome this limitation, SMART is aimed at the design and development of innovative intelligent polymeric scaffolds and implants, exploitable in the field of regenerative medicine and tissue restoration, whose shape and geometrical characteristics can be properly tuned directly by the clinicians in the operating room, in order to perfectly fit with the dimensions and geometries of the portion of the tissue to be regenerated.

The materials will be obtained starting from shape-memory polymers and by manufacturing them by means of emerging technologies such as additive manufacturing/3D-printing and electrospinning. The employment of the emerging technologies will lead to the obtainment of materials presenting complex 3D geometries and controlled microstructures, which will confer to the material novel capabilities, with a resulting increase of the shape-memory properties. Furthermore, the potentialities of the non-thermal plasma technology will be also exploited to endow the materials with surface chemical functionalities in order to promote a more effective integration with the surrounding tissue.

SMART has, as a final aim, the achievement of new solutions to accelerate the procedures for the realization of customized implants and scaffolds perfectly fitting with the patient’s anatomy, with a consequent social impact on the patient’s quality of life and an economic effect on the surgery and manufacturing costs.